SAFETY

We exclusively use our own stabilization resin, ensuring 100% non-toxic raw materials and dyes.

SUSTAINABILITY

We only use domestic wood species, providing a high-quality alternative to tropical hardwoods for the sake of our rainforests.

INDIVIDUALITY

Custom stabilization and coloring techniques tailored to your preferences. The variety knows no bounds for your creativity.

CUSTOMER SERVICE

With over 20 years of experience in wood stabilization, we are a long-term reliable partner where customer satisfaction is paramount.

SAFETY

We exclusively use our own stabilization resin, ensuring 100% non-toxic raw materials and dyes.

SUSTAINABILITY

We only use domestic wood species, providing a high-quality alternative to tropical hardwoods for the sake of our rainforests.

INDIVIDUALITY

Custom stabilization and coloring techniques tailored to your preferences. The variety knows no bounds for your creativity.

CUSTOMER SERVICE

With over 20 years of experience in wood stabilization, we are a long-term reliable partner where customer satisfaction is paramount.

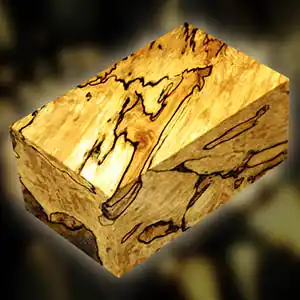

Uni-Color

The Uni-Color process describes stabilization in a full color, transparent, or black with any shading.

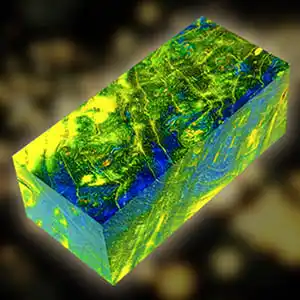

Bi-Color

The Bi-Color process uses two full colors in combination. The balance of the colors can be adjusted according to customer preferences.

Tri-Color

In the Tri-Color process, the item is dyed in three stages. This creates a zonal coloring that, depending on the third color, appears as two to five colors.

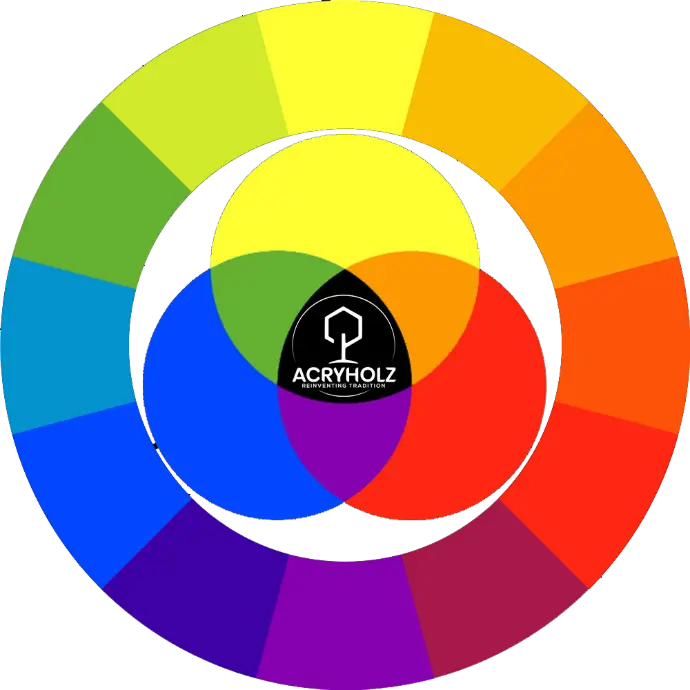

What colors are available?

Within the RYB color system (Red-Yellow-Blue), all primary, secondary, and tertiary colors are possible. The color "white" does not exist because white is a pigment and would be filtered out by the wood structure. The base material is transparent.

How does order stabilization work?

For wood volumes of 3.5 gallons or more, we offer affordable prices and a quick turnaround of only 5 working days from receiving your wood.

Wie kann man Acryholz verwenden?

Our products find applications in various fields, whether as handle blocks or scales for knives, weapons, sports gear (archery, billiard, etc.) or as design elements for interiors or jewelry. Plexiholz is used where decorative materials in constant skin contact are needed. Customers from renowned knife-making companies and the wood industry appreciate our competitively priced and beautiful color variations.

Wie verarbeite ich Acryholz?

PLEXIHOLZ® places great emphasis on transparently informing about the properties of its products. We stress that despite stabilization, our Stabwood should still be treated as wood. Our innovative stabilization technique transforms softwood into hardwood, affecting specific weight, color, and hardness without losing the wood's character. It can be sanded, sawed, turned, milled, and polished like conventional hardwoods, achieving a high-quality, individual, and fascinating effect. While we believe the feel of wood on the skin is preferable to plastic, we stand behind optimized properties such as hydrophobia, dishwasher resistance, or dirt repellency. We understand that PMMA can be influenced by high temperatures and recommend keeping the surface temperature of the workpieces below 175°F. Although PMMA inherently has limited crack-bridging properties and can only partially close natural cracks, we offer creative solutions. We are currently perfecting the ongoing development of the proven process technology we have been using since 2004 to meet the increased quality demands of our customers.

Frederik Wunderlich - Managing Director

The wood stabilization in the puq process was developed in 2002 by my father, Reiner Hochmuth. In 2017, I took over the management and continued my father's successful work. To learn more about PLEXIHOLZ®, write, follow, or call me.